命運的安排,看見腦腫瘤

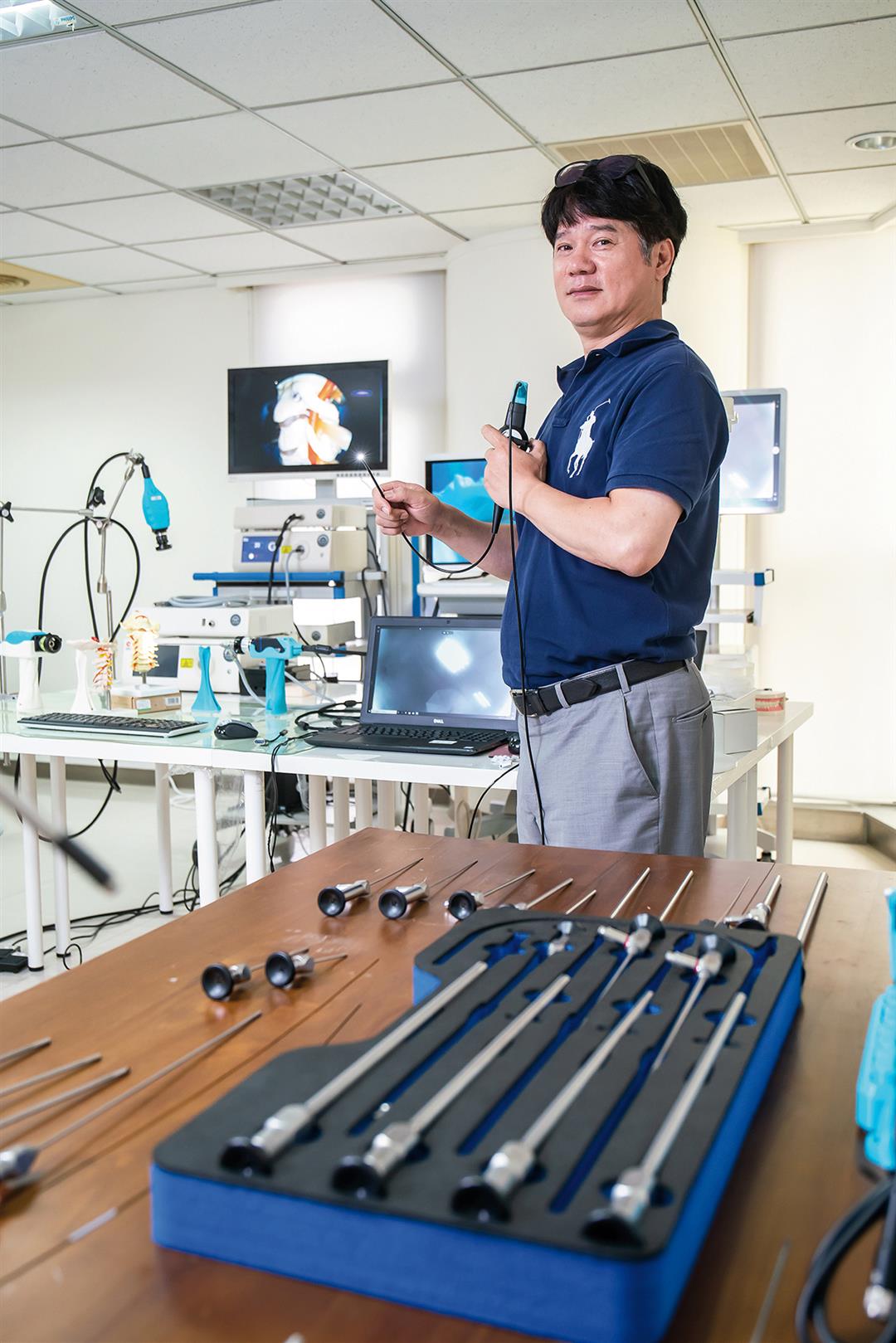

一開始,德盟的醫療內視鏡用於研究教學上,例如成大醫學院等醫學系教授委託德盟,開發供學術使用的子宮鏡、膽道鏡、喉頭鏡,希望能進一步解決臨床上遇到的問題。

真正讓曾湘德感受到醫療內視鏡的威力,是長庚醫院為一位二個月大的嬰兒切除腦部腫瘤的手術,當醫師使用德盟的醫療內視鏡,清楚地照到腫瘤,加以切除,並將取出的腫廇進行病理切片,再次確認是惡性腫瘤時,開刀房一陣歡呼。

全程記錄的曾湘德解釋,在微創內視鏡手術中,醫師靠肉眼無法判定是腫瘤,必須施打5ALA顯影劑,經德盟的內視鏡系統特殊光動力波長一照,吸收顯影劑的腫瘤細胞會呈現粉紅色,讓醫師可以準確切除。

其實內視鏡只能看到腫瘤在那裡,但對醫師而言,還要有相對應的工具來切除它。面對這個困境,德盟進一步把它轉換為商機,再開發「腦神經外科腫瘤切除輔助工具」,為符合醫師的使用習慣,目前已改良至第七代,例如原本考量伸進人腦只要8公分的長度,納入實際手術時情境的考慮後,增長至15公分。

這支看起來像一把精密的工具夾,重量約300公克,開刀時可以向右或向左轉90度,按住或夾住腫瘤後,讓醫師進一步切除,預計在取得衛福部認證後,2021年就可上市。

曾湘德去(2019)年起已在研發磁導式內視鏡,即有導航功能,更可以協助定位發現腫瘤,預計2022年可以完成;目前已成功研發拋棄式的內視鏡,避免重覆感染。

「我當初投入醫療內視鏡,只是一股想幫助人的傻勁,安排我設計的內視鏡可以看到腫瘤。」他再強調說:「這是命運的安排,當時我並沒有想到要挑戰全世界工業技術的限制。」配合政府輔導醫療器材業往微創及人工智慧(AI)發展,醫療內視鏡產業可以成為台灣醫療產業的亮點。

八年來投入醫療內視鏡的研發,協助醫院完成不少成功的手術,曾湘德感觸特別深:「我現在對醫療很了解,很有把握,假如我的母親是現在發現惡性腫瘤的話,我可以用內視鏡找到腫瘤,加上手術、質子治療,結果一定可以不一樣。」

.jpg?w=1080&mode=crop&format=webp&quality=80)

經德盟的內視鏡系統特殊光動力波長一照,吸收顯影劑的腫瘤細胞會呈現粉紅色,讓醫師可以準確切除。(德盟儀器製造有限公司提供)

.jpg?w=1080&mode=crop&format=webp&quality=80)

經德盟的內視鏡系統特殊光動力波長一照,吸收顯影劑的腫瘤細胞會呈現粉紅色,讓醫師可以準確切除。(德盟儀器製造有限公司提供)

.jpg?w=1080&mode=crop&format=webp&quality=80)

經德盟的內視鏡系統特殊光動力波長一照,吸收顯影劑的腫瘤細胞會呈現粉紅色,讓醫師可以準確切除。(德盟儀器製造有限公司提供)

德盟醫療內視鏡未來發展的願景,是與醫學中心合作,依據臨床需求,研發新技術與客製化產品。